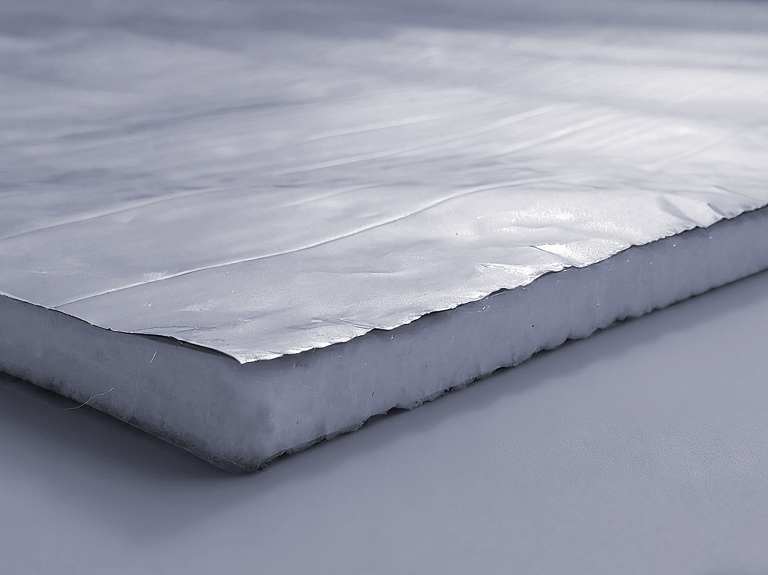

Aerogel blanket is a flexible and efficient thermal insulation blanket. It combines nano aerogel with inorganic fiber and is specially used for cold insulation of various cryogenic industrial pipelines, tanks and other equipment such as liquid nitrogen and LNG. It is an ideal choice for customers to pursue better low-temperature insulation effect and lower energy consumption.

Nano aerogels are known to have very low thermal conductivity in solids. The aerogel blanket is compounded with this super nano material, which is also a soft, environmentally friendly and easy to construct cold insulation material, and conforms to ASTM American Standard C1728 (Type I Grade 1 Category B), making it an excellent product among thermal insulation materials.

Product Center

Cold insulation series

Advantages

-

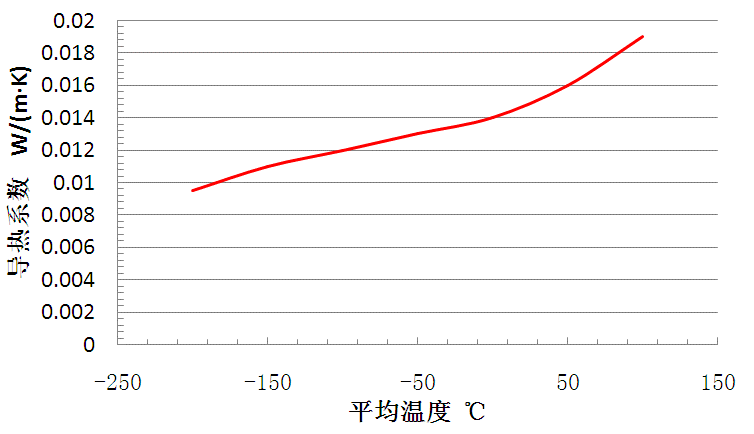

Excellent cold insulation performanceUltra low thermal conductivity, greatly reducing the required thickness, especially suitable for working conditions with limited application space

Excellent cold insulation performanceUltra low thermal conductivity, greatly reducing the required thickness, especially suitable for working conditions with limited application space -

Excellent ultra-low temperature stabilityAt ultra-low temperatures, it can maintain good flexibility, prevent cracking, and resist internal stress caused by pipeline expansion and contraction

Excellent ultra-low temperature stabilityAt ultra-low temperatures, it can maintain good flexibility, prevent cracking, and resist internal stress caused by pipeline expansion and contraction -

Strong hydrophobicity and excellent fire resistanceThe material is hydrophobic as a whole, which can effectively prevent corrosion caused by liquid water contacting pipelines and equipment surfaces, and prevent the insulation effect from decreasing due to water seepage

Strong hydrophobicity and excellent fire resistanceThe material is hydrophobic as a whole, which can effectively prevent corrosion caused by liquid water contacting pipelines and equipment surfaces, and prevent the insulation effect from decreasing due to water seepage -

Easy to constructLightweight, easy to cut and sew to adapt to various shapes of pipes and equipment insulation, and requires less time and manpower for installation

Easy to constructLightweight, easy to cut and sew to adapt to various shapes of pipes and equipment insulation, and requires less time and manpower for installation -

Good structural strengthLong service life, and can be disassembled and reused

Good structural strengthLong service life, and can be disassembled and reused

Physical Properties

| ASTM Test Method | Property | Parameter |

|---|---|---|

| C447 | Service Temperature | -196~125℃ |

| C167 | Density | 80~180(kg/m³) |

| C177 | Apparent Thermal Conductivity, Maximum | @-129℃ 0.014(w/m·k) @-73.3℃ 0.015(w/m·k) @-17.8℃ 0.016(w/m·k) @23.9℃ 0.017(w/m·k) @37.8℃ 0.017(w/m·k) @93.3℃ 0.019(w/m·k) |

| C1101/C1101M | Flexibility | Flexible |

| C1617 | Corrosiveness to Steel | Pass |

| C1104/C1104M | Water Vapor Absorption Rate, by Weight | ≤5% |

| C1338 | Antibacterial Property | Pass |

| E84 | Surface Burning Characteristics | FSI≤25,SDI≤50 |

| C411 | Maximum Exothermic Temperature Rise | Not Applicable |

| C1763 | Water Absorption Rate, by Weight, Before Exposure to 316℃ for 24 Hours | ≤8% |

| C1763 | Water Absorption Rate, by Weight, After Exposure to 316℃ for 24 Hours | Not Applicable |

| C795 | Pressure Corrosion Resistance for Austenitic Stainless Steel | Pass |

| C165 | Compressive Strength, at 10% Deformation | ≥34.5kPa |

| C356 | Linear Shrinkage After Exposure to Maximum Service Temperature, in Length and Width Directions | ≤2% |

| C411 | Anti-sagging, in Thickness Direction | Not Applicable |

Thermal Conductivity